Project Highlights:

- Led mechanical design of a modular, 3D-printable transhumeral prosthetic for field use in low-resource clinics

- Developed parametric upper arm and elbow joint with body-powered cable actuation and swappable end effectors

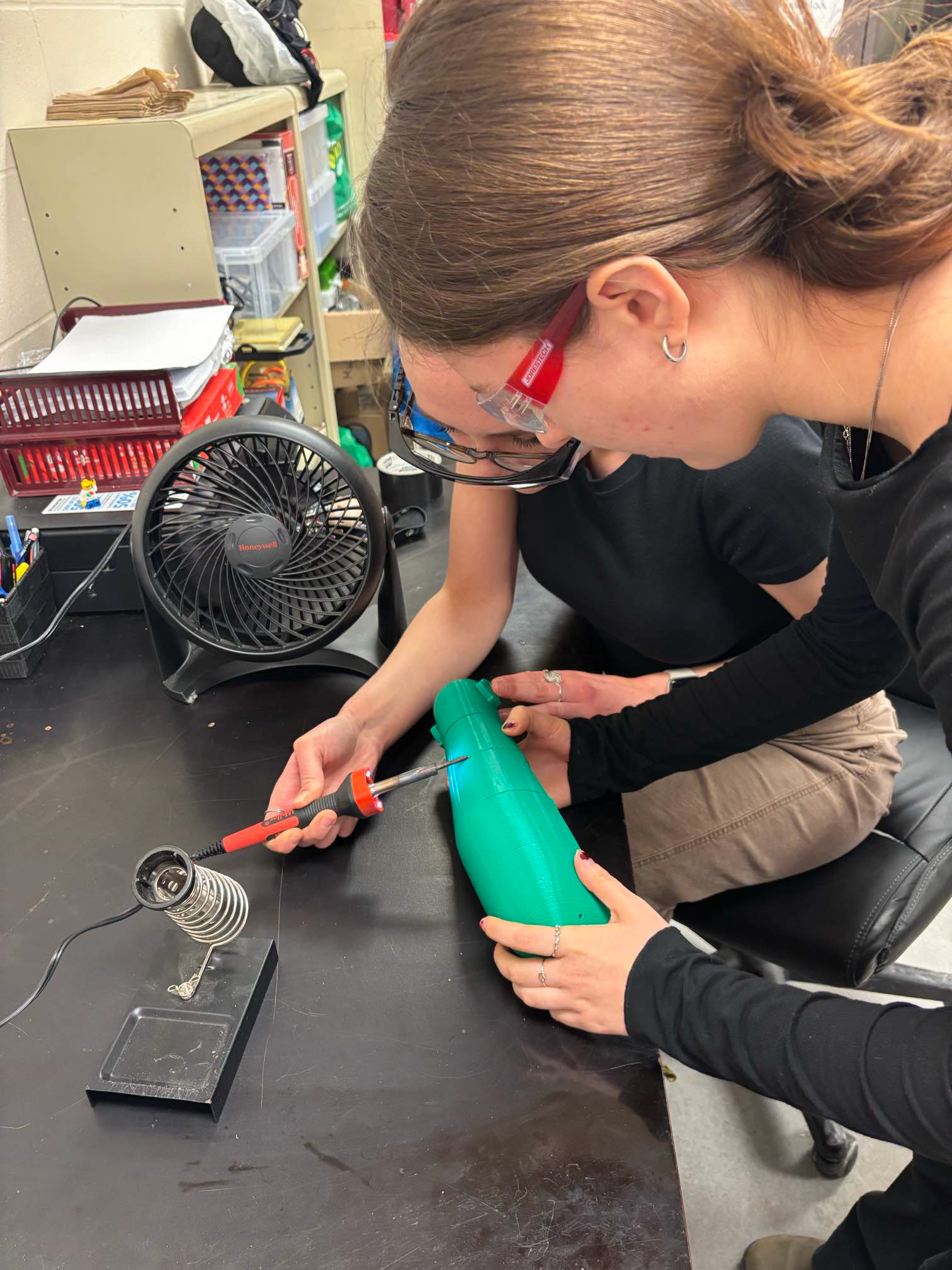

- Validated design through iterative prototyping, benchtop testing, and simulated fitment trials

As part of my work as CTO of the Queen’s Biomedical Innovation Team (QBiT), I joined a humanitarian project in collaboration with the Burma Children’s Medical Fund (BCMF), a nonprofit based in Thailand that supports children affected by conflict. The opportunity came through another student who had begun working with BCMF, and I jumped at the chance before I even knew what the project was.

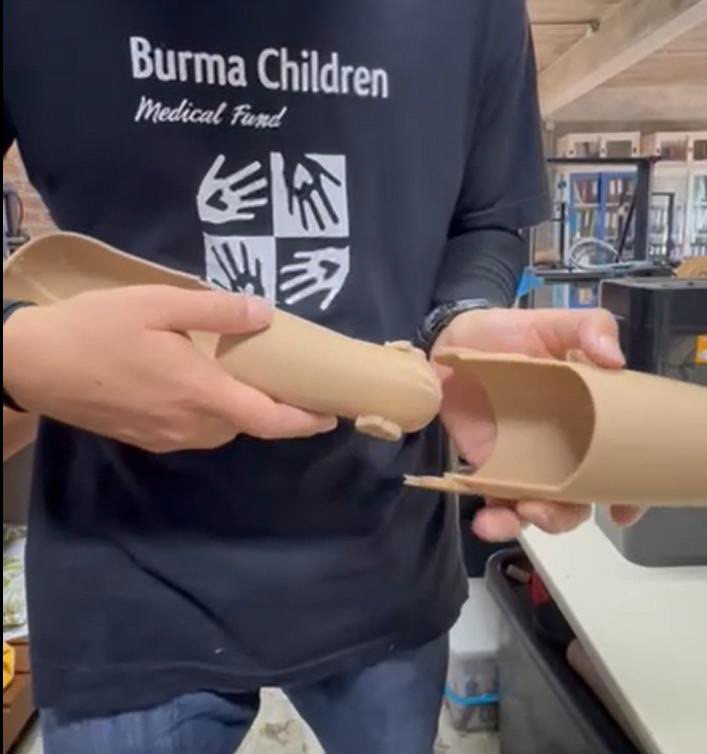

The goal was to adapt an existing 3D-printed transradial (below-the-elbow) prosthetic into a transhumeral (above-the-elbow) system. On paper, it sounded like a small change but in practice, it meant rethinking nearly everything. We needed a new jointed upper arm assembly, a redesigned harness and control system, and to still meet the challenges of reliable field manufacturing using basic FDM printers in rural clinics. I was brought on to lead the mechanical design team, contributing both CAD and project management experience.

We started with user needs and worked with the BCMF technical team in Thailand to gather feedback and validate design decisions. I developed a new upper arm socket and elbow hinge assembly with a cable actuation system, enabling voluntary control of elbow flexion and thumb grasping using a body-powered harness. With our harness systems lead, I helped optimize cable routing and mechanical advantage for intuitive user control.

The device was designed to be parametric and modular, meaning it is adaptable to different users from a single CAD file. We emphasized simplicity and low post-processing requirements to make field assembly possible without specialized tools or training. Key features included simple construction and swappable end effectors for tools or hand attachments.

Prototyping was highly iterative. With each version, we improved printability, force transmission, and range of motion. We bench-tested for durability and actuation forces, and conducted simulated fitment trials to confirm anthropometric compatibility for all users. The final design was transferred to BCMF and will be continued to be improved as the project moves forward.

The project was a rewarding blend of technical design, international collaboration, and humanitarian impact. The team presented our work at the 2025 RICE360 Global Health Design Competition, where it received the Public Invention Award, and at the ASME Summer Bioengineering Conference, where we placed second in the undergraduate track.