Project Highlights:

- Led mechanical design of a modular, sub-$2,000 ECMO system for prehospital and low-resource use

- Integrated pumps, sensors, and thermal control under strict cost, weight, and biocompatibility constraints

- Achieved 98% cost and 46% weight reduction; presented at RICE360 Global Health Design Competition

This project was a turning point for me. It was my first experience in technical project leadership, and the first time I had the chance to present my work at an international engineering competition. As part of the Queen’s Biomedical Innovation Team (QBiT), I was tasked alongside three other project managers with what initially felt like an impossible challenge: to design a portable heart-lung machine, or ECMO system, for use outside of hospitals, in ambulances, remote clinics, and low-resource settings.

ECMO systems are typically complex and confined to ICUs or surgical suites. Our goal was to bring that technology to the field, where power, maintenance, and clinical expertise are all limited. We needed to maintain life-critical function while drastically cutting cost and operational complexity.

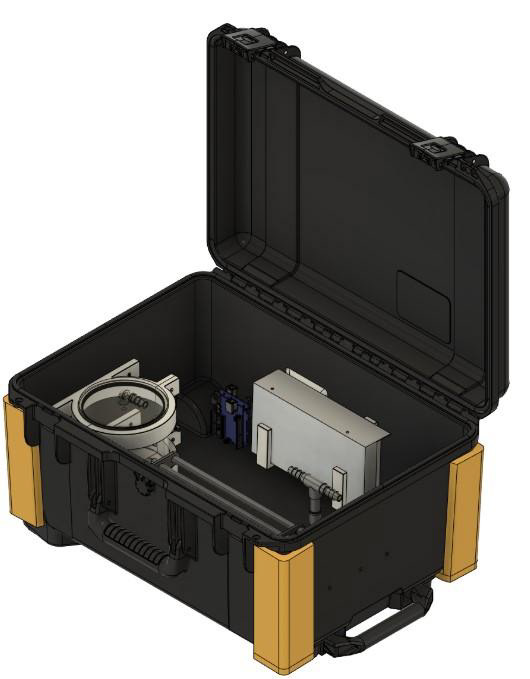

I led the mechanical design team, responsible for the full physical structure of the system. This included designing the membrane and housing, thermal management systems, enclosures, and the overall mounting and integration framework. We also sourced and integrated off-the-shelf components, including pumps, flow meters, pressure and temperature sensors, ensuring biocompatibility, and sterility. We were working under tight constraints, with a target unit cost under $2,000 CAD and a weight below 10 kg, significant reductions from the $100,000+ and 18+ kg commercial systems on the market.

From material research and selection to CAD modeling, and hands-on prototyping using primarily resin and FDM 3D printing, we focused on building a system that was not only compact and cost-effective, but also modular and easy to maintain in the field. We designed for redundancy in critical subsystems and developed testing protocols for flow, pressure, and heat exchange performance to guide future iterations.

Despite the technical and logistical complexity, the project was a huge success. The final prototype achieved a 98% cost reduction and a 46% weight reduction compared to the leading portable ECMO system. It was incredibly rewarding to see our work recognized at the RICE360 Global Health Design Competition in Houston, Texas, where I had the opportunity to present the system to judges from both clinical and engineering backgrounds.

This project pushed me out of my comfort zone in the best way possible. It was hands-on, systems-focused, and people-driven. It taught me how to lead through ambiguity and communicate across disciplines. Most of all, it confirmed for me just how much I enjoy working on problems that matter.