As part of my work as the CTO of QBiT, I was asked to join a third project proposed by another student; to expand on her work with the Burma Children's Medical Fund (BCMF), a nonprofit based in Thailand focused on assisting children fleeing conflict. I jumped at the chance, before even knowing what the project was.

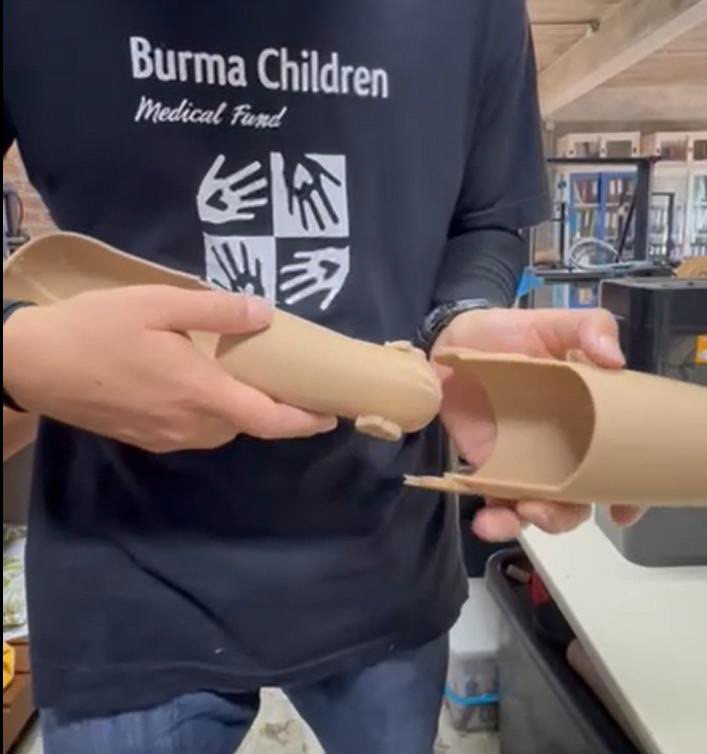

The project proposal was to adapt their currrent 3D printed transradial (below-the-elbow) prosthetic to a transhumeral (above-the-elbow) prosthetic. While seemingly simple, this posed many significant challenges, including requiring new parametric components, a completely redesigned harness and control system, and close collaboration with the BCMF team halfway around the world. I was brought on to lead the mechanical design team for my CAD and project management experience.

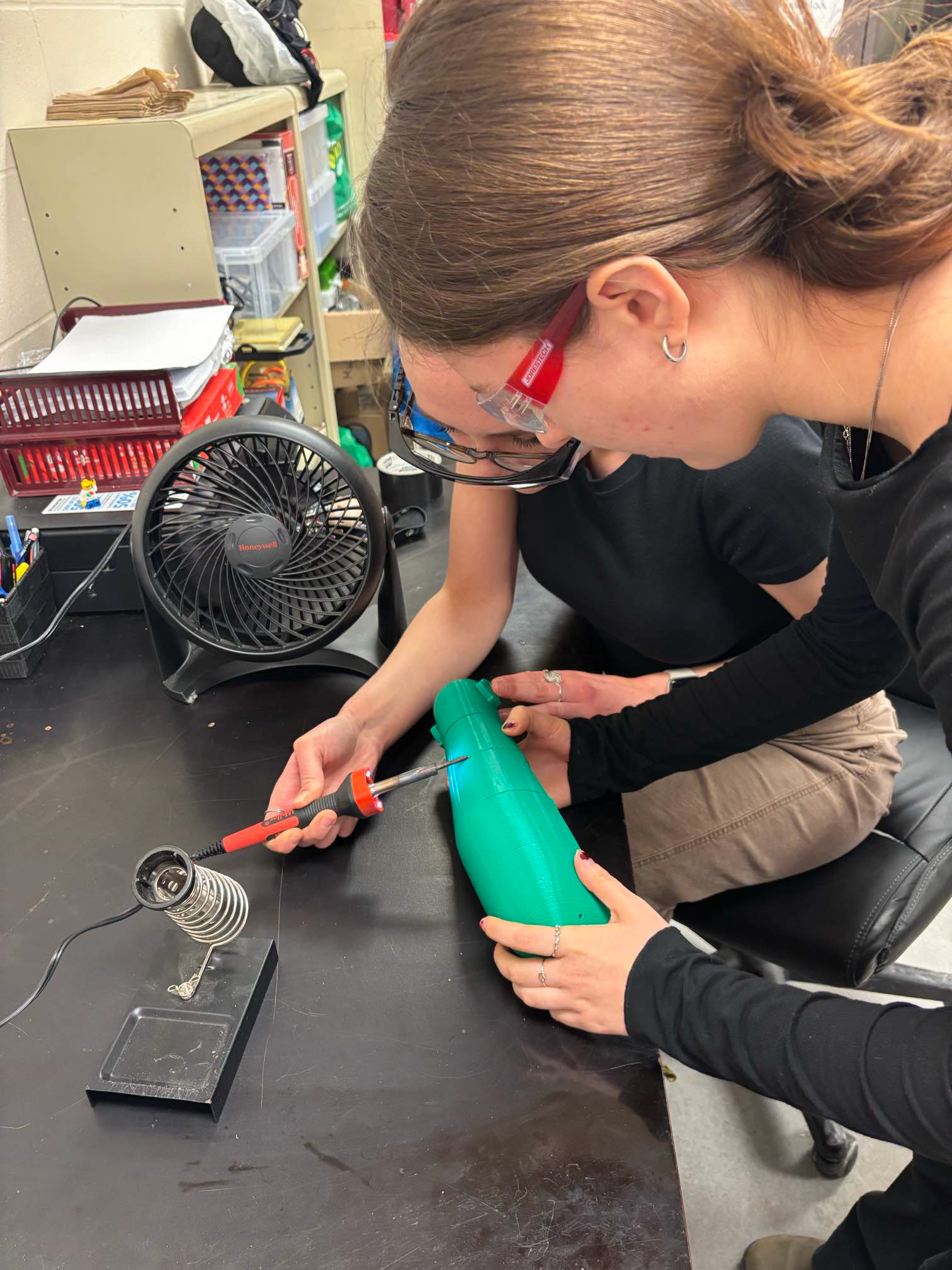

Through the project, I developed and supported team members in the design of a new upper arm and elbow joint assembly, intended to be 3D printed and assembled on-site in Thailand. Our design was informed by discussions with the BCMF technical team, and by rigorous testing and validation. We worked through many prototypes, each improving on the last. Working with the harness team lead, I optimized control wire routing, and developed an actuation mechanism for the elbow and thumb joint enabling simple grip tasks.

Our design features modular, easily interchangeable end effectors, a parametric design to enable custom sizing, and a comfortable, intuitive harness. It has been passed on to the BCMF team and other global collaborators to continue design refinement and continue to impact lives around the world. The team presented our successes, earning the public invention award at the RICE360 Global Health Design Competition, and second place at the ASME Summer Bioengineering Conference in 2025.